How To Build Concrete Walls

Concrete is among the most robust and adaptable materials for walls. You can build a wall to serve as a property marking, a support option, walls for your home, or hold back soil or water by following the instructions in this post.

To be sturdy, a concrete wall must be placed on top of a concrete foundation. After that, reinforce properly, set the forms in position, and pour the concrete to shape your wall. Building a wall is a huge and challenging task, so seek expert assistance or guidance to create a sturdy construction.

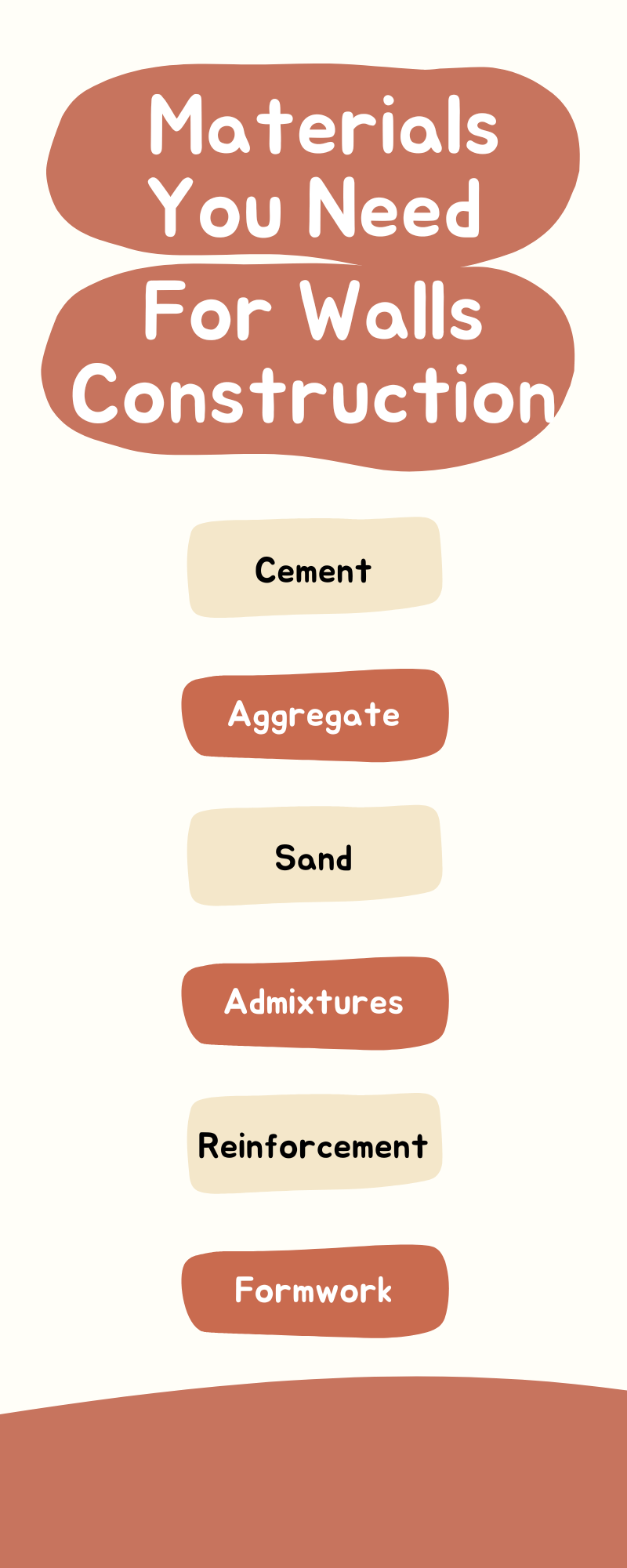

Material You Need

Step 1: Proper Reinforcement

If the wall thickness is less than 100 millimeters, reinforcing bars are usually put in a single layer. If the wall thickness is larger than 200 millimeters, reinforcing bars must be inserted in two layers. Steel bars are arranged horizontally and vertically in a regular grid on the wall. Steel bar size, spacing, and concrete cover must be given with the greatest precision feasible.

You should install reinforcement bars on the tension side of the wall. Steel bars must be extended at construction joints to provide better continuous resistance. Furthermore, it splices with the rebar on the other side, overlapping for a certain distance. The overlap should be given for reinforcement bar ends and steel bar that rounds a corner in the same manner. After the reinforcement has been entirely installed, the formwork fixing process begins.

Step 2: Appropriate Formwork

After the reinforcements have been installed, the following step in the concrete wall building process is to fix the formwork. Various formwork forms are accessible for wall building, including wood, aluminum, and plastic formworks. When deciding on a formwork method, the quality of the produced wall must be taken into account.

However, the superior quality building should not slow down the project or be unprofitable. In most cases, wood formworks are erected on site. Concrete walls are also constructed using prefabricated construction techniques. These formwork systems, which are made of wood with a metal frame or wholly of metal, are meant to connect to one another via pins or latches.

Prefabricated formwork parts come in a variety of shapes and dimensions, and bespoke sizes are often created for special applications. Regardless of the formwork type or technique used, it must be robust enough to withstand the weight of fresh concrete and provide appropriate concrete cover in addition to avoiding concrete leakage through the formwork, which can reduce the structural strength of the concrete wall.

Step 3: Construction Joints

Concrete wall construction joints must be built and placed in such a way that they do not compromise the wall's strength. Roughening the concrete at the interface of construction joints is necessary in order to generate a good connection between previously poured and newly poured concrete.

ACI 350 allows for a maximum distance of 12.19 meters between construction joints and 3.65 meters between a wall corner and a closet design joint. A minimum embedment length of 305 millimeters for joint construction reinforcement must be given on both sides of the joint.

Step 4: Pouring Concrete

You can begin concrete pouring after the formwork, and its ties, pins, and wedges have been correctly secured. To avoid leaks, you can take more appropriate actions. Following that, oil was applied to the formwork surface. Then, using pumps or other relevant procedures, new concrete is placed. Concrete must be compressed when placed and worked around embedded materials, reinforcing and forming corners.

If stay in place forms are utilized, internal vibration must be used to consolidate the concrete. If self-compacting concrete is utilized, however, simply a pin vibrator is used for concrete compression. As a result, there is no need for internal vibration to compact self consolidated concrete.

Step 5: Formwork Removal

Concrete wall formwork can be removed 2 to 3 days after the concrete pouring is completed. The dismantling of concrete wall formworks must be done with care. Heated air curing or curing substances can achieve early removal of formworks in residential homes. This will hasten the construction process.

Step 6: Curing Concrete

The curing procedure and duration may differ depending on the environmental circumstances. If wood forms have been used and left in place, the wall should be maintained wet by sprinkling or another appropriate method. The formwork aids in moisture retention and improves the curing process. Instead, remove the formwork and use a good and practical curing process. If the temperature of the concrete exceeds 5°C, the curing process must extend at least seven days.

Final Thoughts

So this is how you can build concrete walls, and be sure to follow the correct process when doing since no one wants to waste time and money rebuilding pricey walls. Concrete wall construction is a complex operation. It is usually preferable to seek the advice and assistance of a professional.

If you are searching for a concrete contractor for the construction of concrete walls or any other type of concrete construction, call us now for a free quote or visit our site to learn more about us and our concrete-related services.